Industry |

Client Since |

Solution |

| Metal Manufacturing & Distribution | 2023 | Acumatica Manufacturing |

Key Benefits

- Accurate data live from the shop floor

- Significant future growth capabilities & functionality

- Real time access, anywhere

- Strategic, reliable partner

↓ Download Case Study PDF

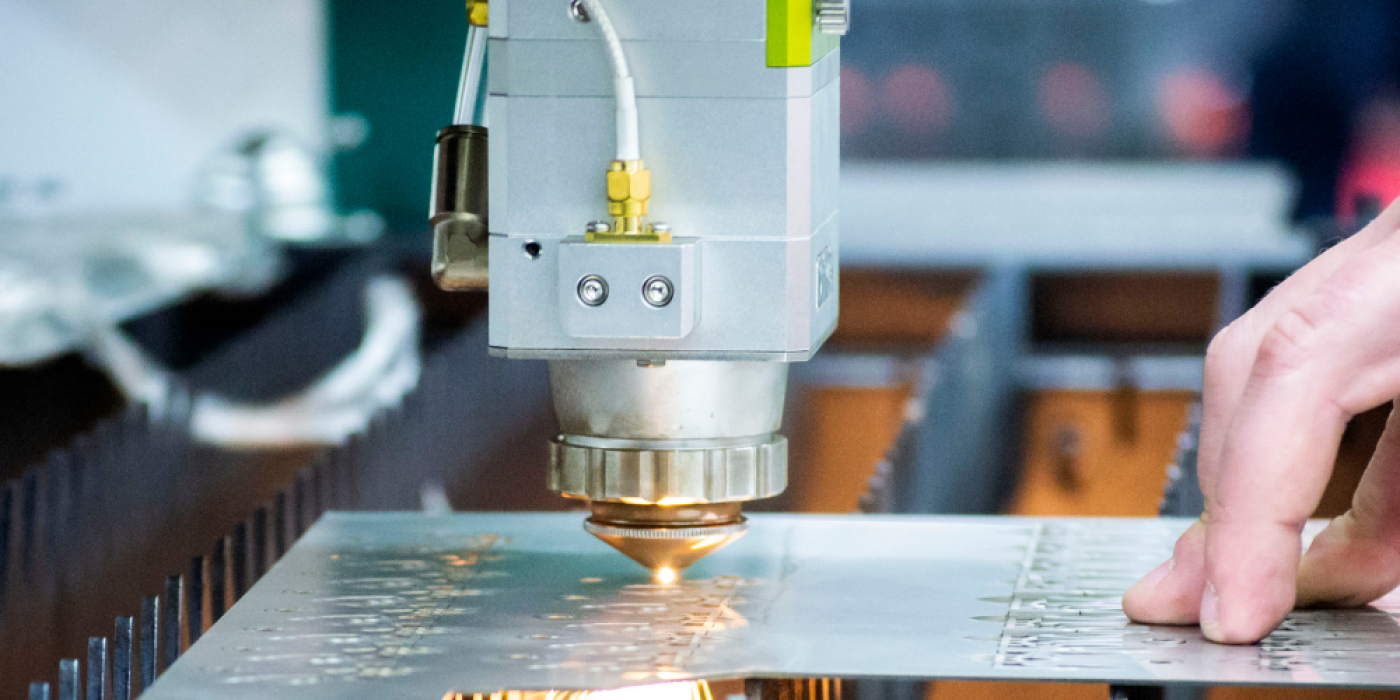

For over 40 years, MC Metalcraft, Inc. has specialized in top-quality custom manufacturing of metal stampings that are not found off the shelf and go inside other components or machines, like clips, clamps, and brackets. As Scott Chakan, President of MC Metalcraft, simply puts it, “We build widgets.” The company’s products have a global reach and are employed by businesses across a wide array of sectors. They also recently diversified into assembly work, which incorporated additional value-added services for their customers, enhancing their growth and service offerings.

Breaking Free of Limitations

MC Metalcraft’s previous system posed major limitations and made it difficult to scale quickly, stay competitive, mitigate security risks, and efficiently manage business processes. The team could only use the system in the office, making it hard to keep up with the flexibility needed not only for remote staff but for modern metal manufacturing as a whole. Seeing the trend towards cloud-based manufacturing, Chakan realized it was crucial to overhaul the system to remain competitive.

Their previous ERP partner exacerbated issues with a significant lack of support. “The delays [were an issue]. If I opened a ticket, I’d get an email 24 hours later. That doesn’t do it in this business – we need answers now,” said Chakan.

Transforming Operations with Simplicity & Scalability

Chakan, who knew Jeff Kaczanowski of Arris Consulting through the local business community, reached out to Jeff. Chakan asked for his advice and expertise on potential options for implementing cloud-based ERP systems. After a careful and thorough assessment, Jeff recommended Acumatica for their business, to give plenty of capacity to grow and evolve. When talking about why they chose Arris as their ERP partner Chakan stated, “The real kicker for me is that these guys are local – they’re here, and they’re very knowledgeable.”

Arris Consulting helped MC Metalcraft tailor an ERP solution to their unique needs through the implementation of Acumatica, a system characterized by its simplicity, scalability, and cloud-friendly capabilities. Acumatica was an easy to use yet still robust, more fitting solution for MC Metalcraft’s requirements. As Chakan stated, “Acumatica and Arris fit us like a glove.” The streamlined workflows, cloud integration, and flexibility to expand with new functionality when needed, such as tablet support, is a big game changer.

An Implementation Rooted in Success

A big part of why the rollout of Acumatica was so successful was attributed to the way Arris handled their pre-implementation phase. Arris collaborated closely with MC Metalcraft, meticulously extracting all data from the old system, and seamlessly transitioning it into the new system with success. Chakan explains, “I think if you’re going to look to implement this type of solution, I would strongly recommend you talk to Arris because of their deep knowledge and experience within the Acumatica platform.”

MC Metalcraft was equally pleased with the implementation. “It went great. Arris did so much leg work on the front end and tested it so many times in the sandbox, that I felt really comfortable.” There were no surprises and everything went according to plan. This seamless transition instilled confidence in the reliability of both Arris and Acumatica. Chakan remarks, “Everything we talked about and everything we laid out happened. Which is always a good thing.”

Success Through Data-Driven Decisions

Acumatica has significantly impacted the ease of use for end-users, especially the Controller, Chakan. The system’s intuitive design saves time by reducing clicks and redundant movements. Everything a person needs to do their work is located on one screen, and if not, they can easily and quickly jump from one screen to the other.

Acumatica also lets MC Metalcraft tailor the different dashboards for different users. Previously, they were navigating through multiple areas and using a disconnected Excel document to track financials which would be outdated as soon as it was created. Now, the essential information is at their fingertips as soon as they log in. Staff can access data anywhere, anytime, significantly improving the day to day for remote staff. Chakan states, “Freedom and flexibility in our workday, day in and day out.” Furthermore, accuracy is improved by eliminating delays and providing up-to-the-minute data from the shop floor. “They’re on the floor and materials are flushing out automatically. Acumatica gives me accurate totals and reads throughout the process where with the old system, I’d have to try to figure out, what did the team use? Having accurate data at my fingertips, which I know is right, has been very helpful for me,” says Chakan. He continues, “It’s a sense of calm just to know that what I’m looking at is real. Data is only good when it’s right, and if it’s useful and something you can trust.”

The Arris team’s expertise in Acumatica played a crucial role in maximizing the value of the solution. Chakan explains it, “They’re truly experts in this program. With Acumatica, they know the ins & outs of the front end and back end. I can come to them and say, ‘Here’s how I want this to work, here’s what I want to see and they can tell me, ‘Well, okay, here’s how we can go about doing that. Or here’s a different way we could go about doing it. Or here’s how we’ve implemented it for others in the past.’”

Forging the Path to Growth

MC Metalcraft admits they are only using a fraction of their new ERP system’s functionality. However, Chakan expresses their commitment and Acumatica’s flexibility to continually evolve in the years to come. Acumatica allows them to implement features that enhance accuracy and usefulness, like the scrap metal inventory feature and others. Chakan is interested in adding more functionality in the future, “We’re only using 20% of the program right now, but we’ll get there.” In the next six months, Chakan plans to find the best way for capturing labor on the job. He’s working closely with Arris to explore barcoding options and evaluating the ease with which operators can scan barcodes from job order pay packets.

MC Metalcraft is very happy with how Acumatica and Arris have transformed their metal manufacturing operations and overall business. They are excited about how Acumatica has positioned them for ongoing success and growth in the dynamic metal manufacturing landscape and are eager of their ongoing partnership with Arris. Chakan added, “Arris Consulting have been a great partner for us. It’s going to be one of those things that I can see us being partners with them for a long time.”